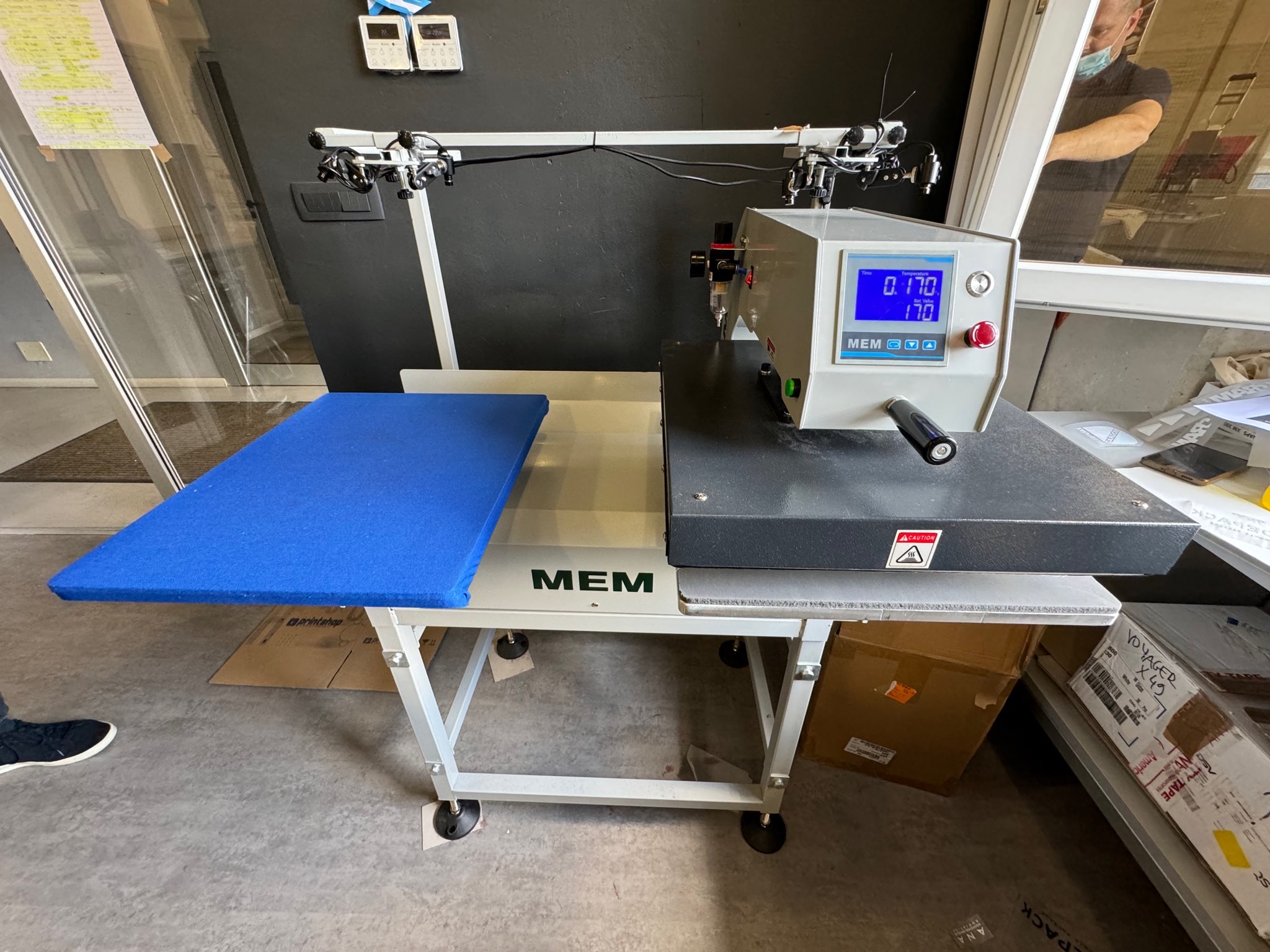

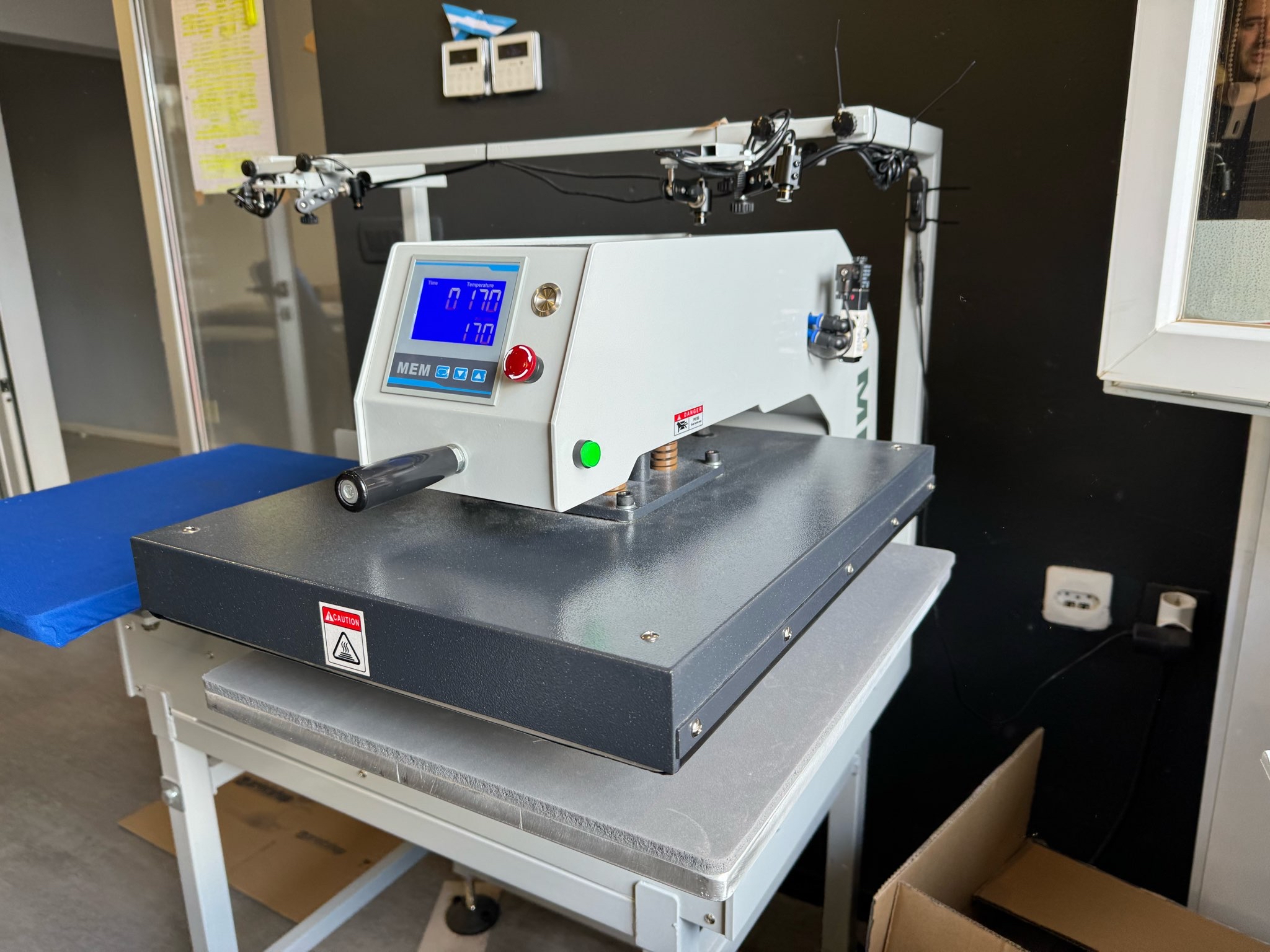

Heat transfer application

Application Instructions

DTF transfers are suitable for application on various types of materials, and the application itself depends on the equipment used, the size of the transfer, and the preparation, i.e., the visual.

Our application recommendations:

Cotton (T-shirts, hoodies, shopping bags) - Temperature 160°C, pressure 12 seconds, peel off the film immediately!

Polyester (umbrellas, backpacks)

PVC

Polyurethane – synthetic leather (menus, notebooks, folders)

For some softer materials (e.g., cardboard, polyurethane, etc.), there is a possibility that the iron print will be visible, so it is recommended to make a test print before printing the entire series and to iron the item over the entire surface if possible.

Pressure 3 to 5 bars

Our transfers are made on high-quality HOT PEEL - double laminated film that is removed immediately after ironing. After the transfer process is complete, gently peel from the side to see if the visual is firmly adhered to the substrate, and if it is, continue pulling the transfer film. For some materials with rougher surfaces, we recommend a short additional ironing of the visual using thermal paper for 3-5 seconds after removing the transfer film.

-

1. Position the transfer

-

2. Iron for 12 seconds

-

3. Gently check the side and peel off

-

4. Remove the film

-

5. Place teflon paper and iron again

-

6. Final result